The journey from coffee cherry to cup begins on the farm, but the real flavor transformation happens after harvest through coffee processing.

The processing method is very important as it can dramatically affect the aromas, acidity, body, and quality of the drink.

Even if the coffee cherry was grown at perfect conditions and picked at peak ripeness, improper processing can lead to defects that decrease value.

Some techniques require more time, investment in equipment, and natural resources than others, making the processing decision critical for the producers.

What is Coffee Processing?

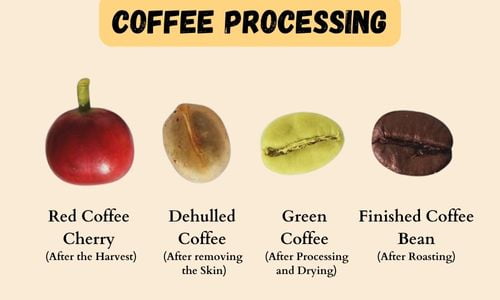

Coffee Processing is the method of converting coffee cherries into finished coffee beans that we use to brew our favorite drink.

The major 4 steps in Coffee processing are:

- Harvesting the Coffee Cherries: The coffee cherry has a seed, pulp, mucilage layer, and outer skin

- Dehulling the Cherries: Removing the outer skin of coffee cherries

- Drying and Fermenting: Beans are left to dry with a layer of fruit to ferment and develop flavors.

- Roasting the Beans: The beans are roasted at high temperatures to bring out flavors and aromas.

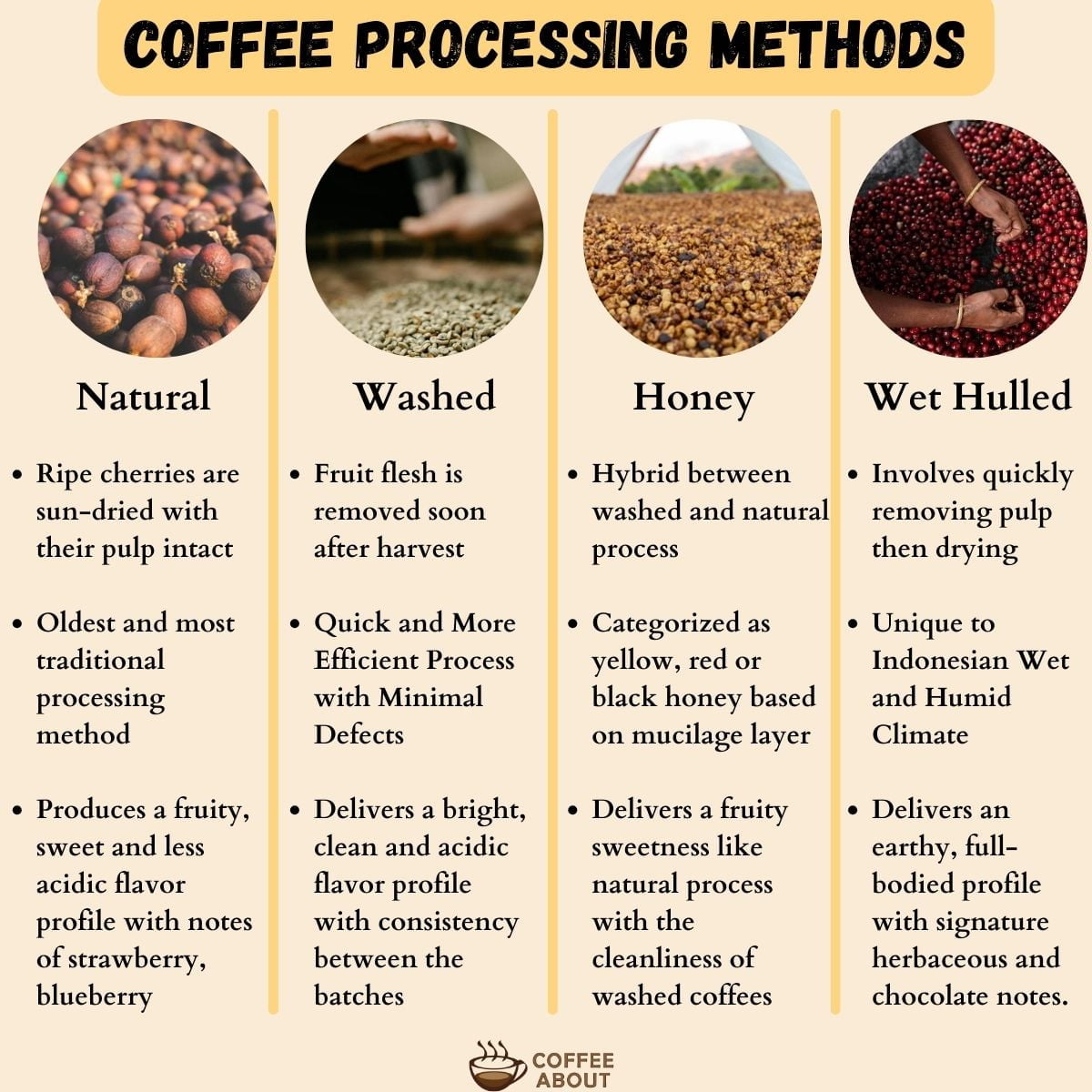

There are several ways to process the cherry and separate the bean, including the natural, washed, and honey methods. Depending on the method it takes 1-4 weeks to process coffee.

The method varies by region based on climate, resources, and objectives. But no single technique is inherently better – each creates unique flavors that coffee lovers can explore!

Anatomy of Coffee fruit

The Coffee bean is covered in five outer layers.

- Outer Skin – The outermost layer that protects the fruit.

- Pulp – The fleshy middle layer of fruit that surrounds the beans.

- Mucilage – The sticky, honey-like layer that coats the beans.

- Parchment – The thin papery layer that covers the bean and comes off while roasting.

- Bean – The seeds inside that are processed into coffee.

4 major Coffee Processing Methods

1. Natural Process Coffee

Natural process, also called dry process, is the oldest method of processing coffee in which the coffee cherries are dried under the sun without removing the outer fruity layer.

It works best in warm, dry climates like Ethiopia, Some parts of Brazil, and other African countries.

In the natural process, first, the ripe cherries are sorted and then laid out to dry for 3-4 weeks under the sun. The cherries are rotated frequently by workers to prevent mold or over-fermentation. Once the cherries are completely dried, the outer layers are removed with the help of machines.

The flavor profile Natural Coffee can be described as fruity, sweet, and very less acidic – often tasting like strawberry, blueberry, or the fresh cherry itself. However, the taste is not very consistent from batch to batch.

The downside is it is a very labor-intensive and time-consuming process and sometimes results in defective beans.

But fans love the complex fruitiness natural processing brings out. It’s a traditional technique still used in many origins today to highlight terroir.

2. Washed Process Coffee

Washed or wet process, is the most common method for processing coffee beans. In this method, the beans are dried without the cherries. The organic matter is stripped soon after the cherries are plucked from the tree.

During the Washed Coffee Process, the ripe cherries are picked and sent to the washing station where they are placed in large water tanks. Under ripe or bad quality cherries float to the top and are removed while the good ones go to the de-pulping machine, removing the outer skin but leaving a sticky mucilage layer. The beans ferment for 18-24 hours in the water allowing the sticky mucilage layer to naturally loosen and detach. The beans then go through successive washings in which they are agitated in tanks of water, scrubbing away all that mucilage completely. Finally, the cleansed green beans are dried outdoors on patios for 1-2 weeks.

The flavor profile of Wet Processed Coffee can be described as bright and clean with pronounced acidity and known for its consistent and crispy taste. It lets you taste the true flavor of beans, not overwhelmed by the fruitiness.

Washed processing requires substantial water resources which can be a drawback in drought-prone areas. But for origins with rainfall, it efficiently yields consistent, high-quality beans in very little time which makes the process very economically feasible.

Washed process is mostly used in Central American Countries and other regions with adequate rainfall. Around 80% of Colombian coffee is washed, known for balanced acidity and crispness.

Read a Guide on Washed vs Natural Coffee

3. Honey Process Coffee

Honey-processed coffee is like a hybrid between washed and natural coffee. After harvesting, cherries are de-pulped but not washed thoroughly and left to dry with their sugary mucilage coating.

The Honey process was originated in Costa Rica just a decade ago and now growing popular throughout the World.

In Honey processing, the outer skin is taken off but the sticky mucilage layer is left fully or partially intact. The beans are then set out to dry while still covered in this honey-like mucilage, which slowly ferments and infuses flavor into the beans. The quality of honey coffee depends on the amount of mucilage left on the beans in the drying phase and the process can be described as yellow, red, and black honey based on that.

The flavor profile of Honey Coffee offers the best of both Worlds – it has fruity and sweet characteristics like Natural Coffee while being crispy and consistent like Washed Coffee.

4. Wet Hulled Process Coffee

Wet hulled processing, also called semi-washed or giling basah, is a unique technique used almost exclusively in Indonesia due to the humid climate.

In the wet-hulled process, producers quickly de-pulp the ripe cherries and then partially dry the beans to 30-40% moisture. This brief pre-drying prepares the bean for removal of the protective parchment layer in the dehulling machine before complete drying. Once hulled, producers spread the beans on patios to finish drying, which often takes up to 4 weeks.

Removing the parchment early allows the beans to dry efficiently in wet and humid Indonesian conditions. However, wet hulling can crack or chip some beans during processing.

The flavor profile of Wet Hulled Process Coffee can be described as herbaceous, full-bodied, and syrupy. It has signature tobocco and chocolaty notes that Indonesian Coffee is known for.

The process is done in a few other places now, but nowhere else produces the intense, cured tobacco note of the Sumatra coffee. – National Geographic

Innovative Coffee Processing Methods

While washed and natural processes are the two most common methods of coffee processing some unconventional processing methods are also gaining popularity in the specialty coffee industry recently.

Carbonic Maceration Processing of coffee

In the Carbon Maceration Process, the whole coffee cherries are placed in a tank and saturated with carbon dioxide. This allows the fruit and seed to ferment together, and the cherries take on a deep purple hue as fermentation progresses.

Carbon maceration is a fermentation technique borrowed from winemaking and it is gaining popularity in coffee processing.

Lower temperatures (4-8°C) produce bright, complex coffees with pronounced acidity. Warmer temperatures (18-20°C) mute acidity but deliver sweet, fruity flavors like bubblegum. After fermentation, the fruit can be processed either through a washed or natural process.

Carbonic maceration coffees are known for their fruit-forward taste profile. The downside is that it requires very expensive specialized tanks. But overall it allows coffee producers to emulate winemaking techniques for new complex tastes.

Carbonic Maceration is a growing trend in specialty coffee as it develops a layered and complex flavor profile.

Anaerobic Processing of Coffee

In Anaerobic processing, The de-pulped coffee cherries are placed in an airtight tank without oxygen. This oxygen-free environment allows fermentation by yeast and bacteria to proceed slowly, for up to 96 hours or more. The microorganisms break down the coffee’s sugars and other compounds, producing alcohols, acids, and esters that impart flavor complexity.

Anaerobic fermentation is an innovative technique for controlling and extending the fermentation during coffee processing.

Anaerobic coffees are prized for their clean, fruity, and floral flavors. A downside is that the specialized tanks and gas equipment make it an expensive process requiring technical expertise.

Anaerobic processing is trending in Panamanian farms to bring out unique flavors from prized Geisha Coffee beans. In the 2023 Barista Championship, nine of the total 18 competitors used a Gesha, seven undergoing anaerobic fermentation.

Read a Guide on Fermented Coffee

What after the processing?

Once coffee cherries are processed as washed, natural, or other methods, the beans still have a parchment layer around them.

At this stage, moisture levels are low enough to prevent further fermentation or rotting of the bean. These green coffee beans are transported to warehouses for storage before being exported to coffee roasting companies.

Before export, the coffee beans are repeatedly sampled in a process called “cupping.” This involves expert tasters critically evaluating the aroma, flavor, acidity, body, and other qualities of coffee beans. This quality assessment helps define the taste profile and value of that particular coffee harvest.

The final stage is roasting. Roasters apply heat to transform the green beans into the brown, aromatic product we know. In the roasting process, the intense heat breaks down the cellular structure of the bean and develops rich flavors and aromas.

Read a guide on 4 types of Coffee Roasts

Final Thoughts

And that wraps up our deep dive into the science and art behind coffee processing! I hope you now have a fuller appreciation for how big an impact the processing method can have on the flavors and qualities you taste in your morning cup of joe.

For Coffee lovers, this knowledge can help you better understand and describe the tasting notes in your favorite bags of coffee.

I’d love to hear your thoughts on this coffee processing! Have you tasted the difference processing makes in certain coffees? Share your experiences in the comments below!

Check out related articles